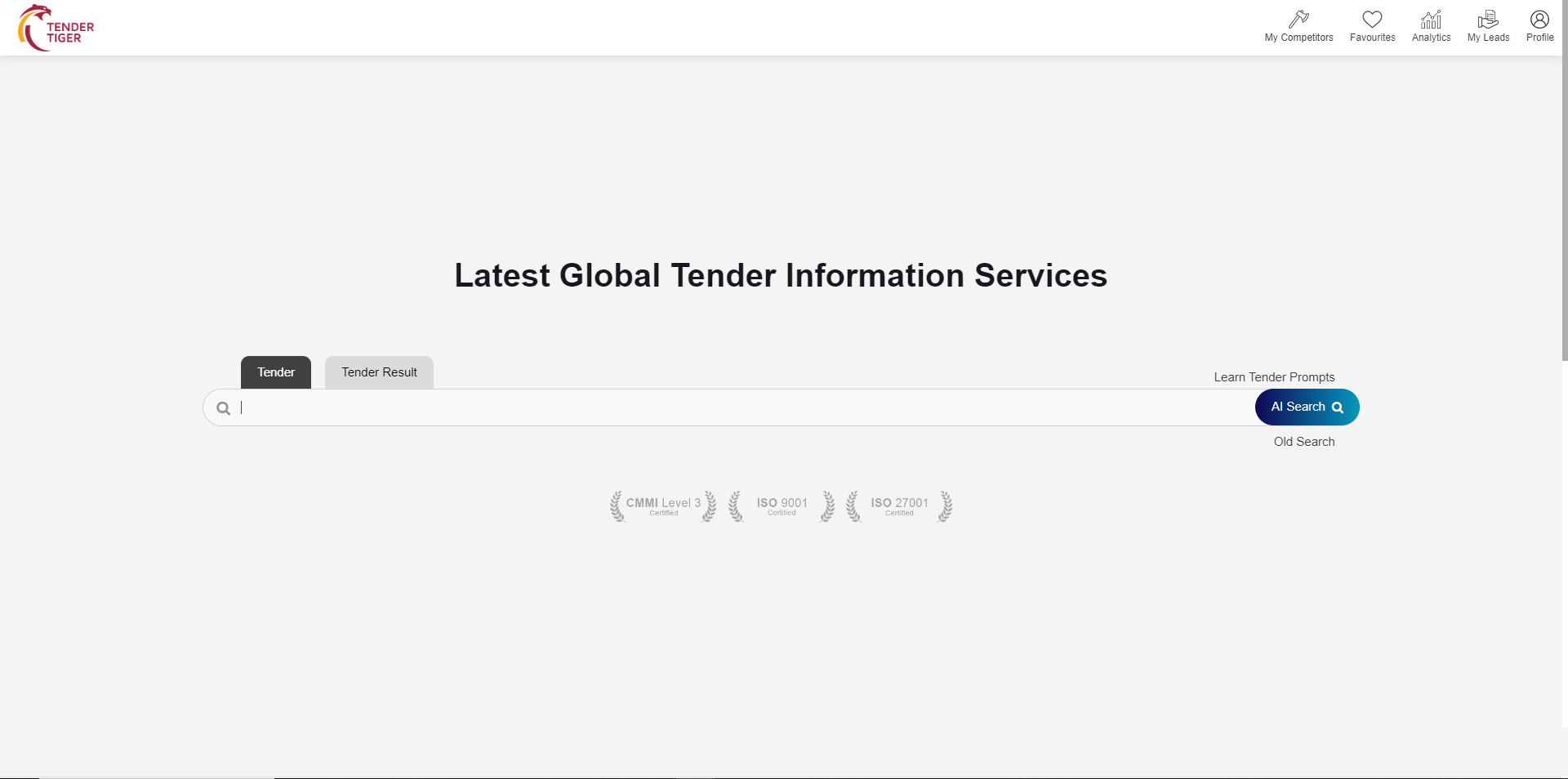

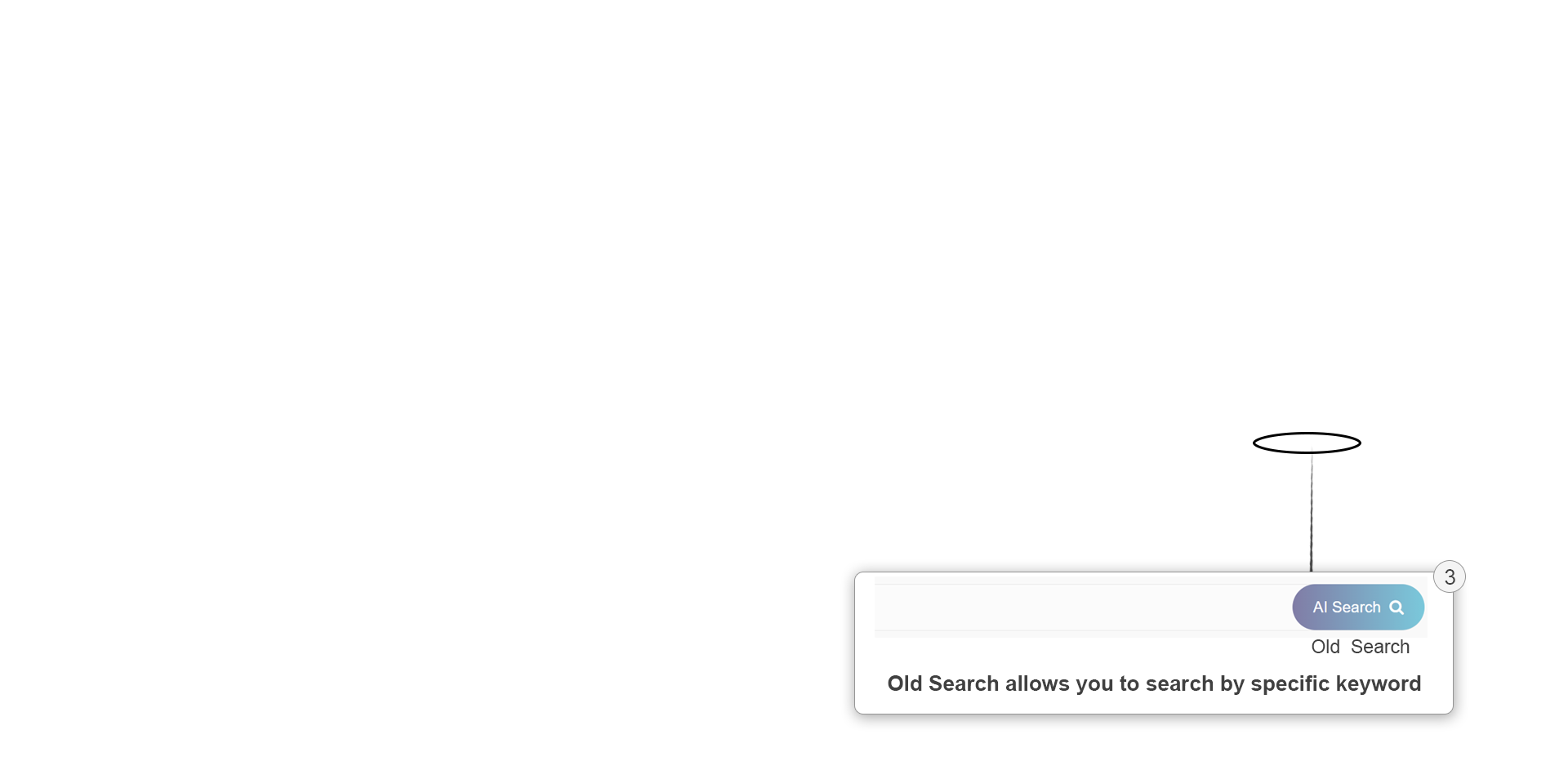

Live/Old

Live/Old

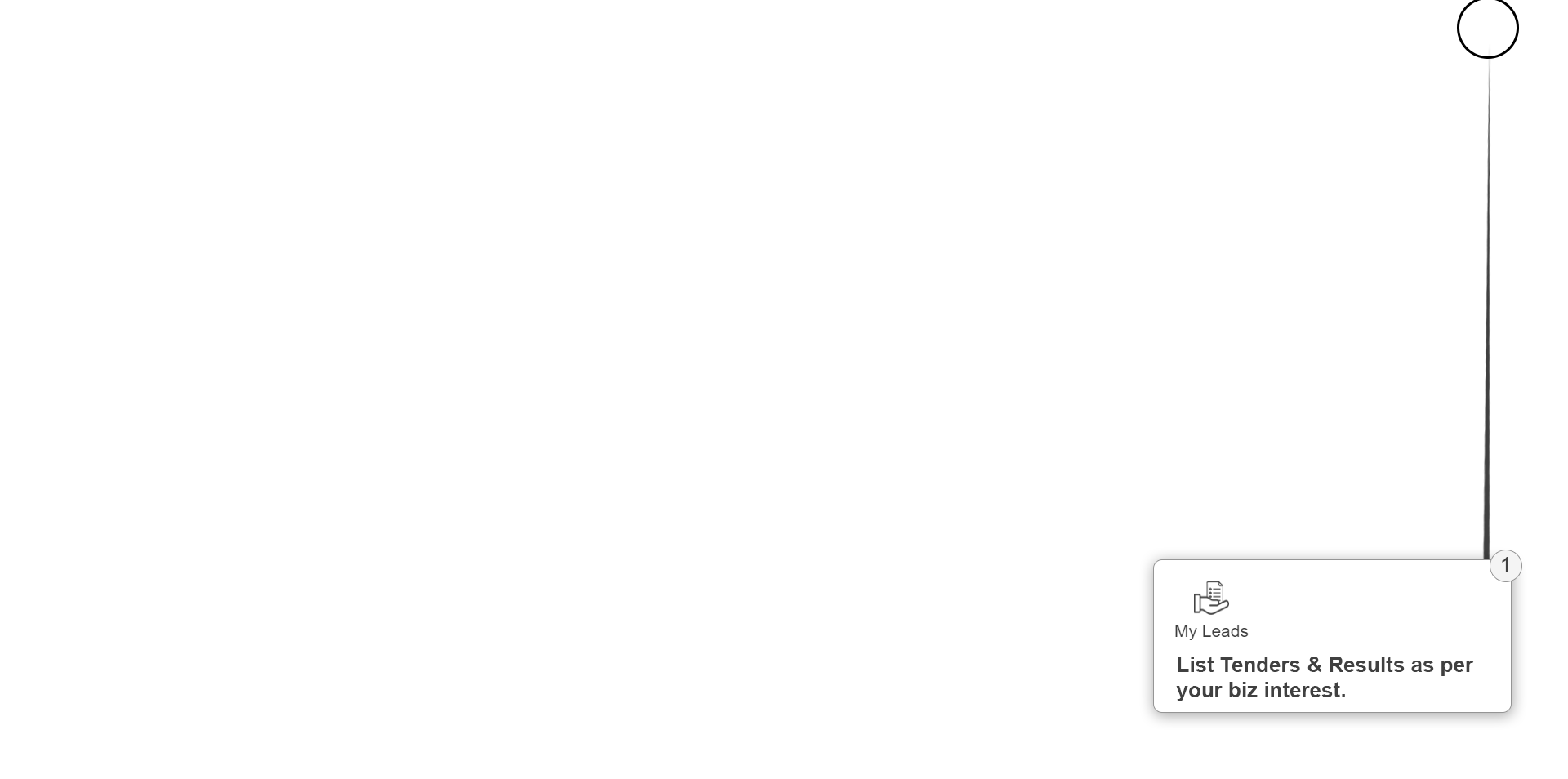

- Live

- New

- Archive - 2025

- Archive - 2024

- Archive - 2023

- Archive - 2022

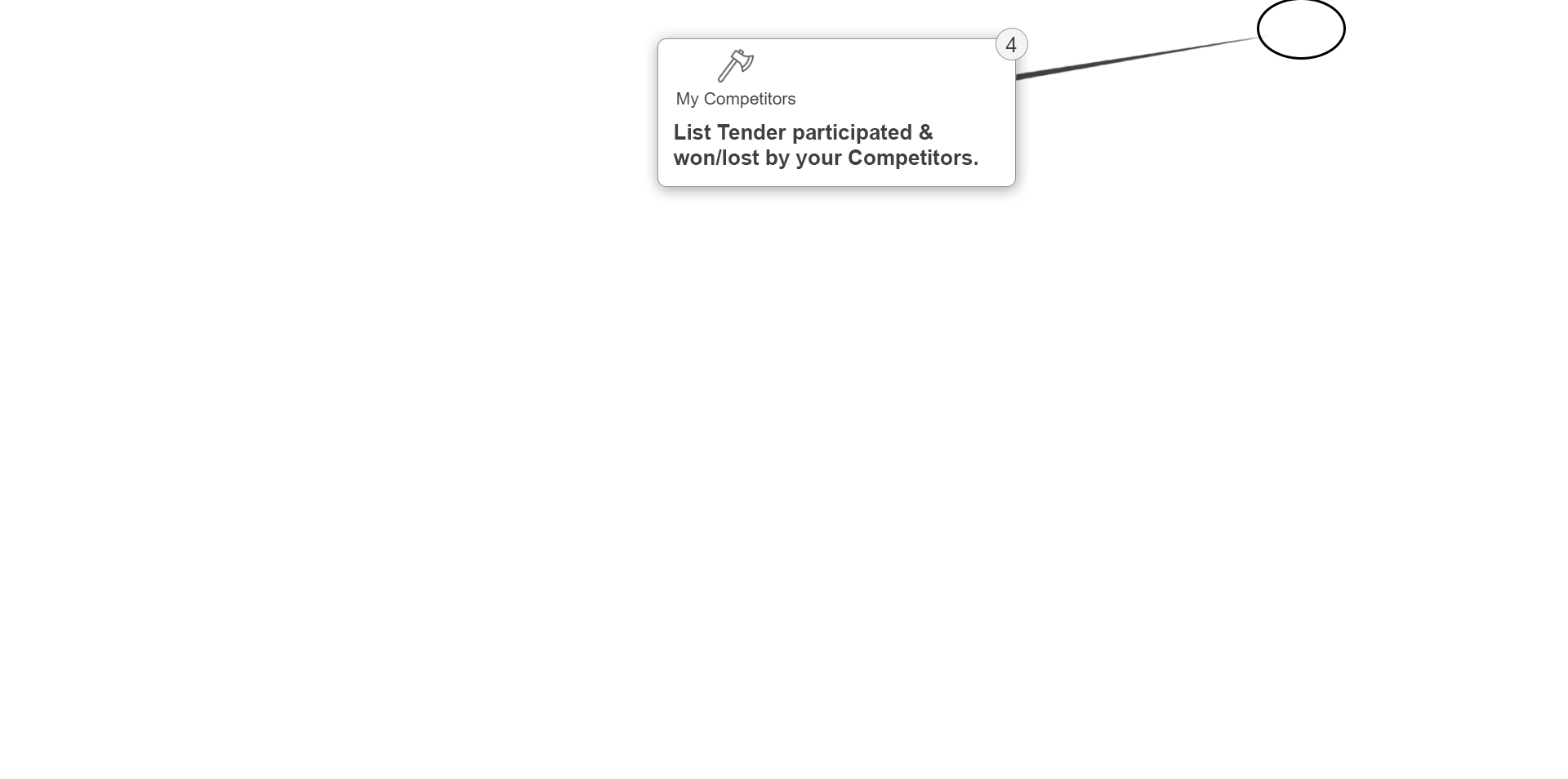

Filter

Filter

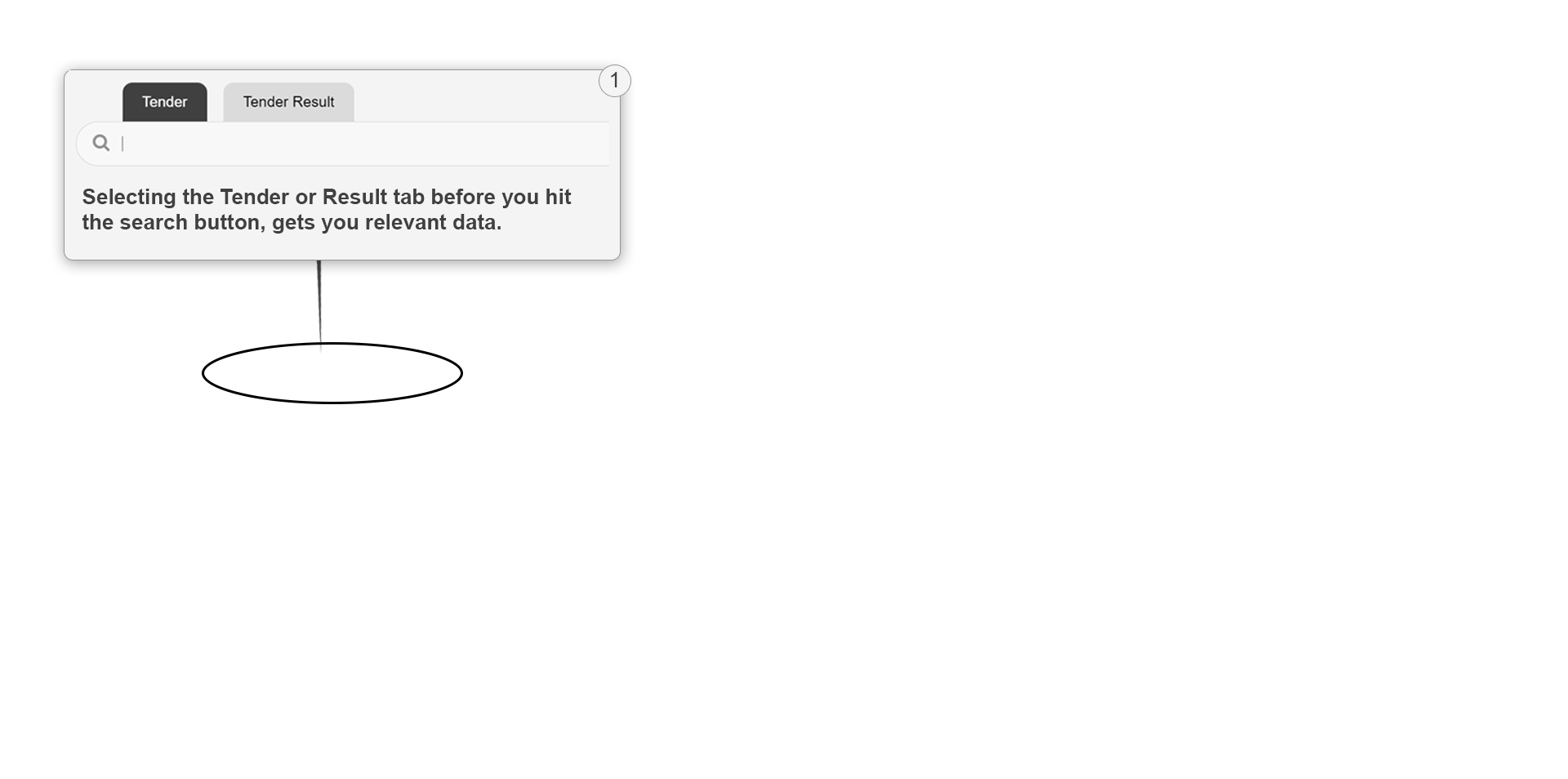

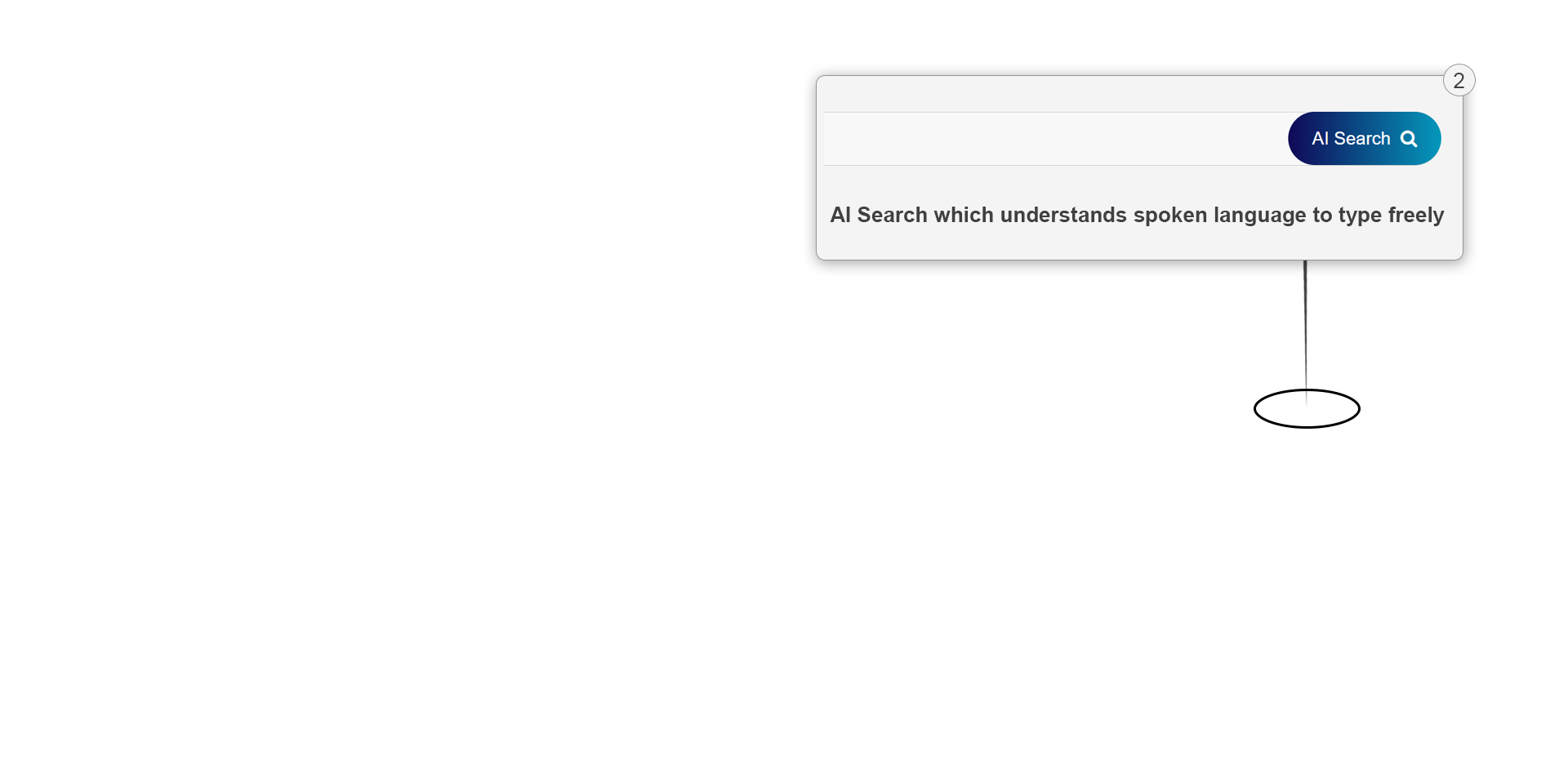

History

History